Many stamping organizations are shifting away from the standard practice of Chroming their dies for improved life and surface quality. As opposed to surface bonding associated with the Chroming process, Ion Nitriding relies on the diffusion of nitrogen in the surface of the steel, forming a metallurgical bond with greater strength and durability. This substrate treatment still allows Tool and Die makers to work the punch, cavity, and/or binder surfaces to improve surface condition.

The Process & Benefits of Ion Nitriding Die Surface Treatment

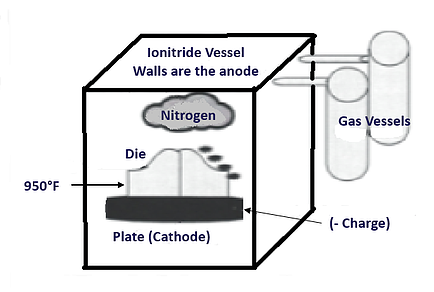

Ion Nitriding consists of a holding vessel, Cathode, anode, heat, alloying elements, and a controlled atmosphere. The die component will be placed on a plate and loaded into the holding vessel. The internal nitrogen-enriched atmosphere is heated slowly to around 950⁰F, where any remaining contaminants are burned off from the casting, and some residual stresses from the machining processes are relaxed.

Figure 1

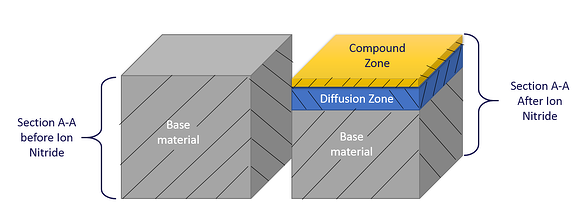

In this low-pressure process (Figure 1), a voltage is applied between the component and the furnace wall, resulting in a glow discharge with a high ionization level generated around the parts. On the surface area that is directly charged by the ions, nitrogen-rich nitrides are formed and decompose, bombarding active nitrogen into the surface. The nitrogen forms compounds with alloying elements in the casting (Figure 2), such as CrN; these yield extreme hardness (>58 HRC) and great wear and fatigue resistance . The case depth of this metallurgical layer ranges in depth from 0.0006 inches (15 microns) to as much as 0.0035 inch, depending upon the application requirements and intended life between maintenance treatments.

Figure 2

The die is held at this temperature for a specified length of time to achieve the intended case depth of the hardened layer and is then slowly cooled to room temperature. Slow cooling ensures uniformity of the hardness and minimizes the risk of stress cracks on the surface. After the die is brought back to room temperature, the surface will have a slight layer of scale from this process. The scale is removed, and the die is ready for polishing.

Considerations Before Ion Nitriding Die Surface Treatment

There are a few things that should be considered before Ion Nitriding the die. First, negative conditions such as a bad radius prior to Ion Nitriding will be preserved by this process– in this example, the bad radius will remain after Ion Nitriding. Second, the surface shine will not be the same as chroming, but when polished correctly, the reduction of friction will last longer because the hardness depth is greater compared to a traditional chrome layer.

PVD Die Coatings: Enhancing Tool Performance with Physical Vapor Deposition

Ion nitriding is a substrate treatment similar to heat treating, but stampers also use different coating practices to prolong tool life. The most common method is called Physical Vapor Deposition (PVD), which describes a variety of vacuum deposition methods used to produce thin films. PVD uses physical processes such as heating or sputtering to produce a vapor of material, which is then deposited on the object requiring coating.

Standard industrial coatings applied by PVD are:

- Titanium nitride (TiN)

- Chromium nitride (CrN)

- Titanium aluminum nitride (TiAlN)

The process involves applying a low heat temperature of about 420°F for deposition, with a processing temperature of 750°F. The most common coating chemistry used is CrN (chromium nitride) developing a thickness ranging from 1-4 microns. This process provides various benefits such as chemical and heat resistance, increased hardness, high wear resistance, improved lubricity, low coefficient of friction (0.5), and oxidation resistance. Due to the low temperatures required during PVD coating, there should be little to no part distortion if the substrate material has been heat-treated to the specifications required for coating.

CVD Die Coatings: Utilizing Chemical Vapor Deposition for Tool Longevity

Less common than PVD but still widely used, Chemical Vapor Deposition (CVD) is an atmosphere-controlled process conducted at elevated temperatures (approximately 1925°F) in a CVD reactor. During this process, thin-film coatings are formed as a result of reactions between various gaseous phases and the heated surface of substrates within the CVD reactor. Distinct coating layers are formed on the tooling substrate as different gases are transported through the reactor.

Partner with Phoenix for Improved Tool Life

At Phoenix, we understand the importance of advanced surface treatments and coatings in enhancing tool life and performance. Our team is dedicated to assisting you in selecting the best surface treatment solutions to meet your specific needs, ensuring improved durability, reduced maintenance costs, and enhanced overall productivity.

If you’re interested in learning how The Phoenix Group can drive improvement at all levels of your organization, contact us today.