WHAT IS FORMABILITY SYSTEMS IMPROVEMENT?

Formability systems improvement is the analysis and optimization of formability processes in manufacturing, such as tool and die, sheet metal forming, and metal stamping. As an ongoing process followed with discipline, it can lead to significant improvements in cost efficiency and loss reduction. Below are 4 advantages to having a long-term relationship with Formability System experts, to ensure that the formability system improvements you achieve are sustainable.

ONGOING FORMABILITY SYSTEMS CONSULTING MAKES CONTINUOUS OPTIMIZATION MORE LIKELY

Finding, evaluating, and choosing a company to partner with for formability systems consulting is a significant and important task, because the partner acts as the catalyst that drives improvements. As personnel, facilities, technologies and processes change within the manufacturing plant, the expert consultant maintains the vision and stability necessary to have a sustaining system with lasting results. Committing to a formability systems consultant for the long-term means you consistently have a trusted voice guiding your implementation success. And their focus is singular, whereas employees must frequently manage multiple responsibilities that compete for attention and priority.

THE ORGANIZATION YOU PARTNER WITH DOESN’T HAVE TO RELEARN NEW SYSTEMS EVERY TIME

Your systems are complex. Employees need significant time and training investment before they can make a meaningful contribution to your organization, and external consultants are no different. A long-term partnership eliminates the necessity of costly, time-consuming onboarding, brings stability and continuity to improvement objectives, and keeps your operation lean and effective. In time, these partners understand your process, your employees, and your operation as well as your own team.

WORKING WITH A PARTNER THAT’S FAMILIAR WITH YOUR ORGANIZATION GENERATES LONG-TERM COST SAVINGS

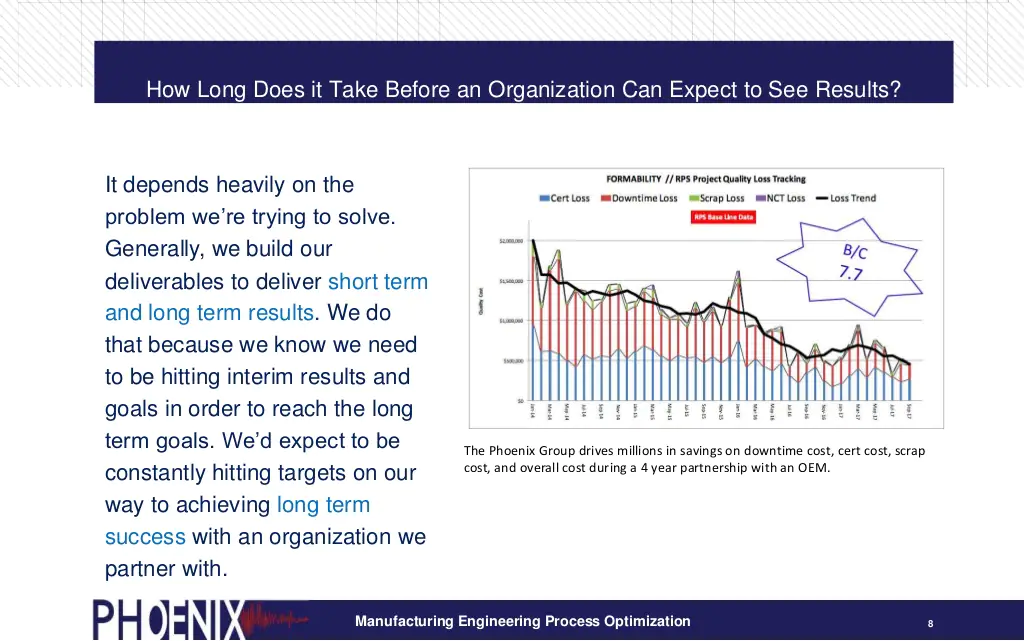

The empirical data is inarguable — a long-term partnership with a formability systems consulting team drives significant savings over time. The system acts as a foundation for continuous improvement, and new projects or opportunities are more efficiently executed as a result. The long-term partner understands this foundation, and builds upon it, as opposed to recreating a process that inevitably slows savings. An organization must also be leery of one-off projects or events — with ample focus, they can generate fast results, but these decay over time without a system to support and cause lasting change. As a result, a one-time process improvement project won’t have the same impact on your bottom line in the long term.

LONG-TERM PARTNERSHIPS DRIVE BOTH TECHNICAL AND CULTURAL CHANGE!

Formability processes should be optimized to drive improvements in process robustness and part quality; in doing so, losses from scrap and downtime are minimized. Sustained improvements in these performance metrics have a side benefit — employee morale and confidence is boosted. Effecting change takes time, investment, and a deep understanding of an organization’s systems — and an expert partner and coach is needed to steer the change process.

The below slide deck shows real data from an OEM that partnered with The Phoenix Group from 2014-2017, driving improvement at all levels of the forming process. Through familiarity with existing systems, expert knowledge of how and when to implement each formability system element, and a relationship built on long-term trust and results, our customer achieved millions in savings on downtime cost, certification costs, scrap cost, and overall costs during the engagement.