The Value Of The Rapid Plant Assessment Process

LEARN WHY THE RPA PROCESS IS USED SO FREQUENTLY BY TOP MANUFACTURERS AROUND THE GLOBE WHAT IS THE RAPID PLANT ASSESSMENT PROCESS? The Rapid Plant Assessment (RPA) process is a…

LEARN WHY THE RPA PROCESS IS USED SO FREQUENTLY BY TOP MANUFACTURERS AROUND THE GLOBE WHAT IS THE RAPID PLANT ASSESSMENT PROCESS? The Rapid Plant Assessment (RPA) process is a…

HOW THE MANUFACTURING INDUSTRY CAN MANAGE CHALLENGES BROUGHT ON BY TRADE TARIFFS WHAT ARE YOUR OPTIONS FOR DEALING WITH TRADE TARIFFS? If you work in the manufacturing industry, then you…

In 2020, the automotive tooling spend is almost one-third below the total from 2019. What does this mean? For starters, one of the main reasons behind this decline is the…

George Coates Mar 9, 2021 11:32:10 AM Tuesday, February 16th at 3:30pm EST, George Coates will be speaking at the Battery Electric Vehicle Architectures conference. George will be accompanied by…

You’ve paid for training. Your team members have read a variety of management books on all of the latest processes. Your recruitment has landed highly credentialed talent. You’ve paid for…

Heating a piece of metal until it glows cherry red and while still hot, forming it into a usable shape isn’t new. Hot forging existed before modern times and is…

For nearly 30 years The Phoenix Group has been the Conscience professing that to get consistent part quality and problem free set and run die exchanges, standardization and control of…

https://www.youtube.com/watch?v=8w4fRnB3IlU Formability analysis is a crucial aspect of material engineering, especially in industries like automotive manufacturing. This process involves various techniques such as circle grid analysis and thickness strain analysis,…

In the past, Die makers would review the trim or cut edge for signs of increased work hardening during the cutting processes. They would examine the sheet metal for burr…

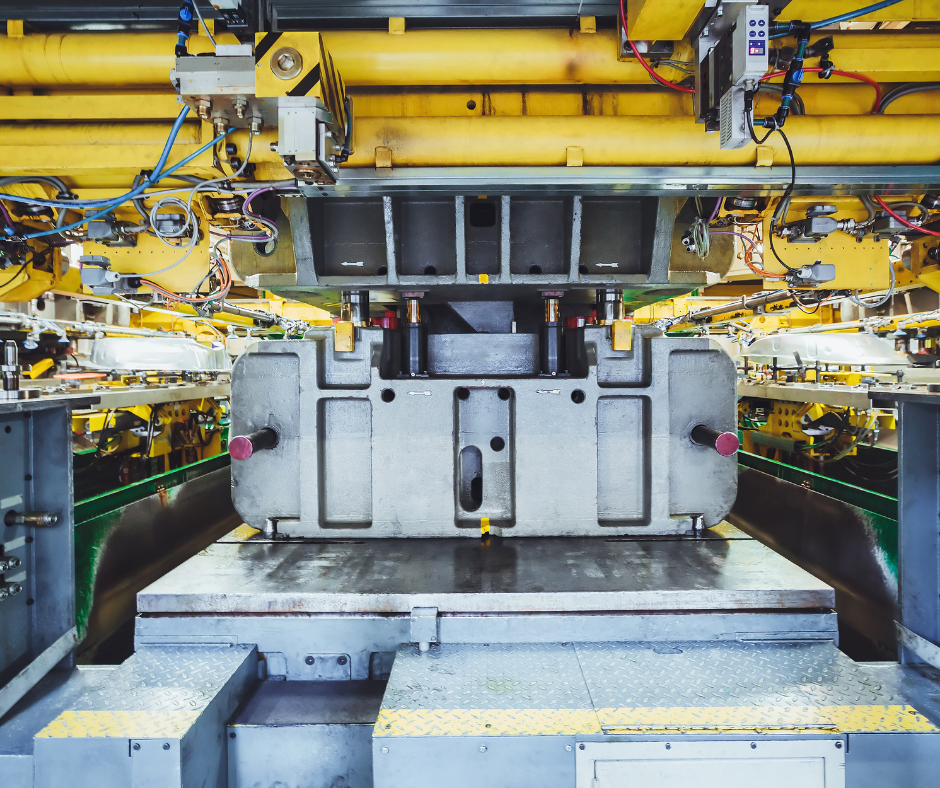

The value added by a stamping operation, is to create distortions with a Sheet metal component commonly referred to as “Part Shape”. The vertical press motion is transformed, by the…